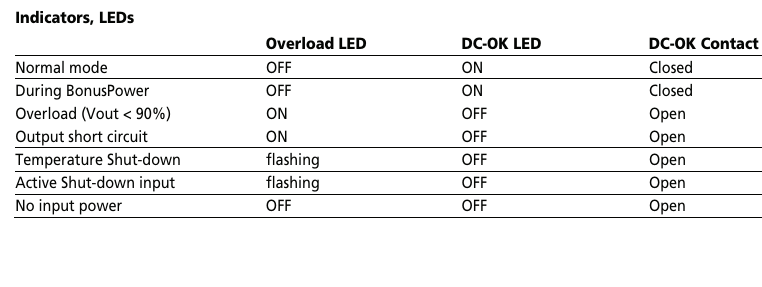

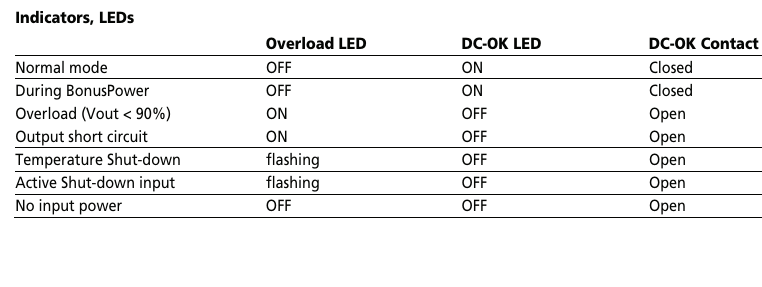

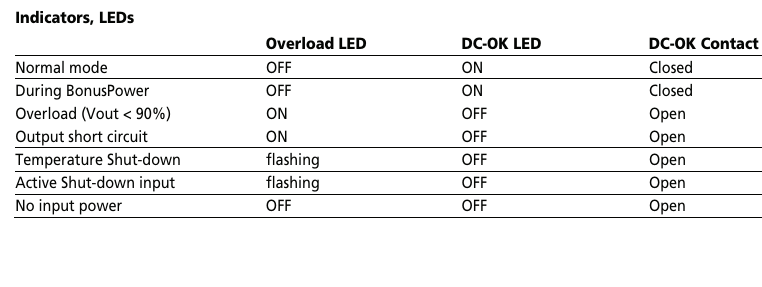

Here's a list of the LED indicators that can help with your mystery problem.

Obsolete industrial electronics forum is still alive and well, just undergoing some maintenance and more anti spam stuff, stand by for a better experience

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Show posts Menu

We use both first and third-party cookies on this website. Cookies are small text files, stored on your computer that help provide advertising and give you the best experience while visitng our site. By continuing to use the site without changing settings, you are agreeing to our use of cookies. Read our complete cookie policy.