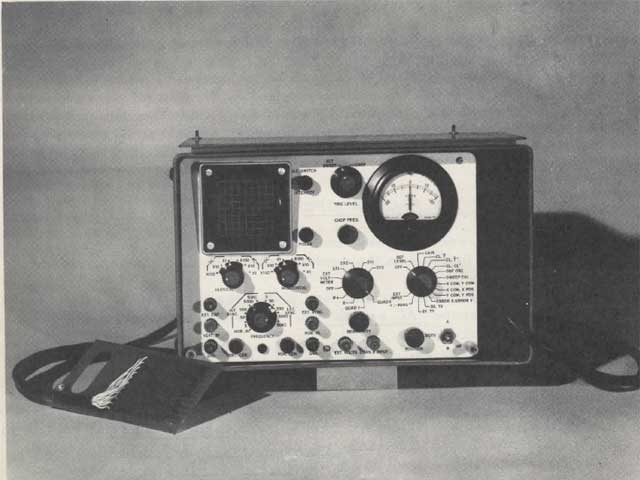

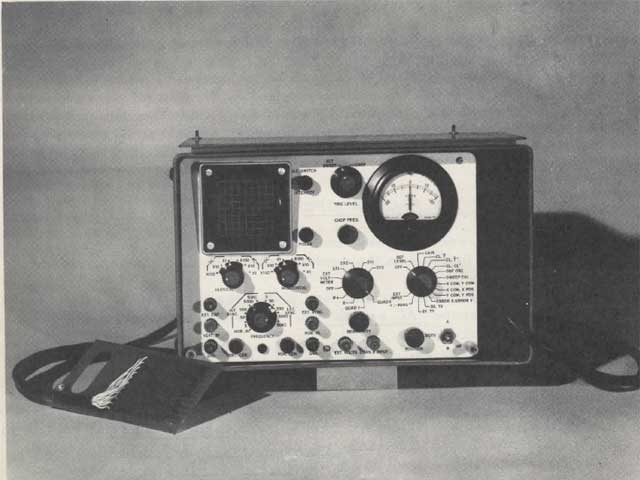

The Proboscope is an electronic test unit with a built-in dual trace oscilloscope and meter specifically designed so that certain test points in the P&W Tape-O-Matic control unit could be examined.

This is definitely a dedicated piece of test equipment for a very old piece of technology. The control units on these old NC machines includes in its design a plug-in card receptacle for the Proboscope connector.

This is definitely a dedicated piece of test equipment for a very old piece of technology. The control units on these old NC machines includes in its design a plug-in card receptacle for the Proboscope connector.